Quality - Inspection - Construction

services

What is Quality?

Quality is a measure of distinction or a state of being free from defects, deficiencies, and substantial deviations, brought about by the firm and consistent adherence to measurable and tolerable standards to attain uniformity of output that fulfills specific customer requirements.

According to International Organisation for Standardization (ISO), Quality is “The totality of characteristics of an entity that bear on its ability to satisfy stated needs”

As per Project Management Body of Knowledge, i.e., PMBOK’s Philosophy, Quality must be planned in and not inspected in. Prevention is more important than inspection.

Quality Inspection

These are actions aimed at checking, testing or measuring of products and to share the results to the requirements to authorise compliance. Quality inspection is very much concerned on post construction check on products or activities. Therefore it doesn’t have direct impact over construction process. The role of Quality Engineer or Manager is to differentiate products or activities and will not allow any kind of substandard quality with respect to the specification and standards.

Quality inspection procedure is carried out in 3 main objects

1. Identification of the Quality issue ( Root cause analysis)

2. Provision of information to respective in charges or Project managers (Information for taking corrective actions)

3. Elimination of the issue by Managers (Preventive measures to be taken care for not to reoccur the issue)

Quality Assurance :

Quality Assurance or QA is the process of identifying or determining all the quality requirements for a project, classifying prevailing quality documents such as specifications, codes, etc. that are significant to the quality requirements of the project and making them accessible for use, preparation of new project specific quality documents such as Project Specific Quality Plan (PSQP) or Project Quality Plan (PQP) or Quality Assurance Plan (QAP), Inspection Test Plans (ITP), Job Procedures (JP), Project Specifications etc. that would provide the necessary structure or procedures for ensuring that the planned or targeted quality requirements or quality goals for the project are completed in timely and an organized manner.

Two important principles included in QA are: "Fit for purpose", the product should be suitable for the planned purpose; and "Right First Time", mistakes should be eliminated.

The Project Quality Plan (PQP) or Quality Assurance Plan (QAP) is the most elegant quality document in a project site. Preferably, it provides the complete structure or comprehensive procedures for achieving the target quality for all phases involving the project like scope, planning, design, development, execution, procurement, records and document control etc.

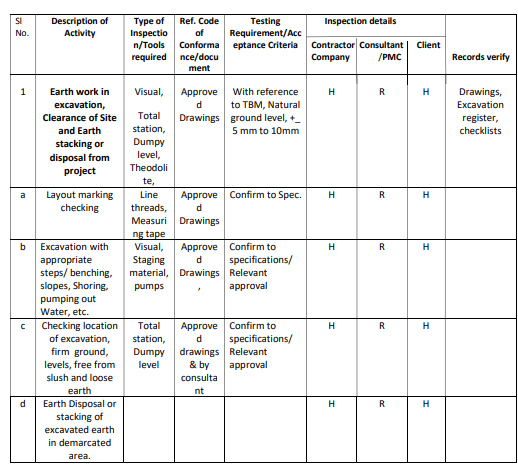

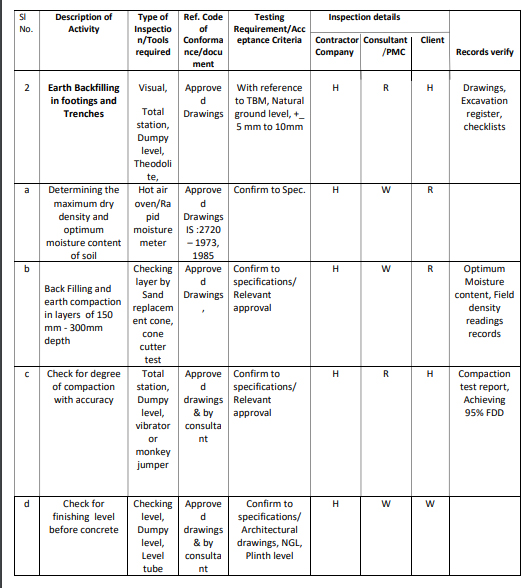

A sample of PQP for Inspection and Test plan for all construction works at project site is given below.

INSPECTION AND TEST PLAN FOR ALL CONSTUCTION WORKS AT PROJECT SITE

LEGEND: H – HOLD POINT, W – WITNESS, R – REVIEW RECORD, M – MONITOR,

Connect with us to avail a complete construction services

CONTACT US

15/4, gurunath 2 A cross Hanumagirinagar, Chikkallasandra Main Road Subramanyapura,

Bengaluru – 560061

info@myhomemydesign.in

Our Happy Clients

Client Testimonials

I whole heartily congratulate the unique website “My Home My Design’ which gives immense pleasure and information about construction aspects. The top categories covers all topics of civil engineering & construction technology, highly useful to professionals & people wants to build their houses in a complete satisfactory manner without lack of engineering knowledge. Now they can proudly feel the happy results. I look forward more and more information in future which benefits all people throughout the country.

Shri Srinivasa Narasimaiah is a highly knowledgeable, practical man strict to the Quality Principles in construction methods as well as materials and not comprising at any cost.

LLP, Ex-President- RMC Readymix (India)

With 27 Plus years of vast Experience in construction field, Shri N.Srinivasa is Chief Quality Auditor, guide,strength &backbone for all our projects as far as quality & workmanship is concerned.

Really superb, this website shares immense knowledge about A- Z of construction activities in a standard and technical way. The ideas, caution, advice at suitable places highlights the creator’s practical exposure and experience in the subject. Similarly photos, description and videos gives immense knowledge for all construction aspects. I wish all the success for this website and likewise spread this useful information to the people across the globe.

PraveenShrusti Design Consultants

Shri Srinivasa Narasimaiah was the main pillar behind our Prana Medical centre construction from start to finish including Plan, Construction, Quality, workmanship and timely completion.Without his cooperation the project wouldn't have been completed on time.

MBBS and Chairman at PRANA MEDICAL CENTER, SPECIALIST CENTER FOR DIABETES, ENDOCRINE,

OBESITY. – Kodambakkam – Chennai- 600024

Previous

Next

Always Dedicated & Devoted

Latest Projects

Excavation for basement and footing

October 16, 2019

Compaction of Concrete

October 10, 2019

Building ByeLaws for Residential Buildings – All You Wanted to Know

September 22, 2019

How to Plaster Your House? Guide for Home Plastering

July 19, 2019

EXTERIOR PAINTS – PAINTING WORKS

July 19, 2019

CONCRETE – RCC WORKS IN CONSTRUCTION – PART1

July 19, 2019